WeEn Semiconductors Delivers Optimal Solution for Supercharging Modules

As the “heart” of charging stations, the performance and reliability of charging modules are undeniably crucial. The popularization of the "super charging" concept has made long cruising range and short charging time become the selling points of more and more electric vehicles on the market.

Recently, the newly released Chinese Standard GB/T20234-2023, which focuses on Part 4: High-Power DC Charging Interfaces for Electric Vehicle Conductive Charging Couplers, has been significantly revised to expand the voltage range to 1500Vdc and the corresponding current range to 1000A. Additionally, the standard now includes new provisions related to liquid-cooled charging stations.

This means that in the future, higher-power megawatt-level charging stations will gradually become a reality. As long as your electric vehicle supports supercharging, it will be as convenient as refueling at a gas station.

Charging Module Technology Analysis

In fact, WeEn Semiconductors has long focused its business on the “low-carbon” track, while acknowledging that charging stations, as crucial supporting infrastructure, will evolve towards directions of higher power, greater efficiency, full liquid cooling, and comprehensive supercharging capabilities.

WeEn's latest research and development effort, the BYC100MW-600PT2, will enable customers to achieve designs for 40kW+ high-power, high-efficiency charging modules. The WND60P20W will offer customers a higher voltage design margin to meet the demands of more complex and ichallenging application scenarios, thereby supporting the rapid development of new energy vehicles and the achievement of low-carbon objectives.

A charging module is essentially a power electronics converter that converts alternating current (AC) from power grid into direct current (DC) that can be stored in the battery of an electric vehicle.

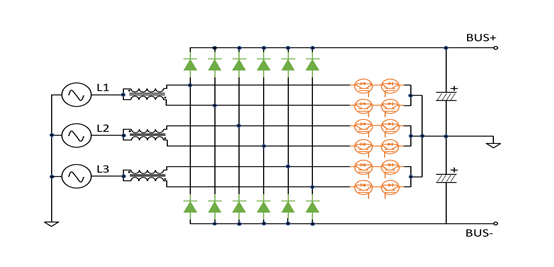

Charging module converters typically have a two-stage topology. The first stage is usually a three-phase Power Factor Correction (PFC), most often using the Vienna PFC topology. Its main function is to convert AC to DC and to correct the power factor.

Figure 2: Vienna PFC Topology Architecture

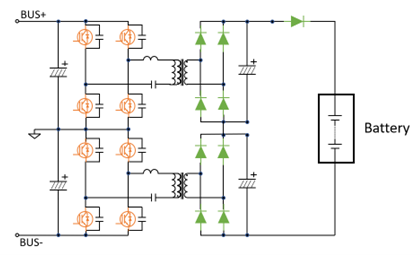

The second stage typically involves a DC-DC conversion, most often using the high-efficiency LLC topology. This stage primarily converts the high voltage DC output from the PFC (800Vdc) into a wide range of adjustable DC voltages from 200Vdc to 1000Vdc, to match the needs of different battery voltage levels. Additionally, the DC-DC stage also achieves electrical isolation from the power grid through a high-frequency transformer.

Since the current charging modules are primarily used for delivering power to electric vehicles, the output rectification in the DC-DC stage commonly employs Fast Recovery Diodes (FRD). Benefiting from the negative temperature coefficient characteristics of Fast Recovery Diodes (FRD), and given that the LLC topology generally does not require stringent reverse recovery performance, FRDs are particularly suitable for use in charging modules that operate under high temperature and high current conditions.

Benefiting from the negative temperature coefficient characteristics of Fast Recovery Diodes (FRD), and given that the LLC topology generally does not require stringent reverse recovery performance, FRDs are particularly suitable for use in charging modules that operate under high temperature and high current conditions.

Figure 3: LLC DC- DC Topology Architecture

Currently, the mainstream power ratings for charging modules on the market range from 20kW to 40kW. Superchargers typically operate by outputting through several charging modules connected in parallel. Therefore, to ensure that each module is not affected by others during startup, Oring diodes are essential. When functioning normally, these diodes are in a conducting state, primarily incurring conduction losses. Consequently, standard rectifier diodes with low forward voltage (VF) are the best choice.

WeEn's Professional Solutions

WeEn semiconductors, including the BYC75W-600P for LLC secondary-side rectification and the Oring diode WND60P16W, have been mass-produced reliably for years in leading charging module manufacturers’ 30kW models. With the recent trend towards higher power in charging modules and the need to accommodate for the harsh operating environments of charging stations, we have responded to our customers’ actual needs by launching the BYC100MW-600PT2 for 40kW charging modules and the higher voltage-resistant WND60P20W, helping our customers solve practical application issues.

#BYC100MW-600PT2 Features:

- Maximum current up to 100A

- Extremely low reverse leakage current

- Optimal VF-QRR trade-off performance

- Robust Eas capability

#WND60P20W Features:

- Maximum reverse voltage up to 2000 Vdc

- Extremely low forward conduction voltage drop

- Enhanced forward surge current capability

- Robust Eas capability

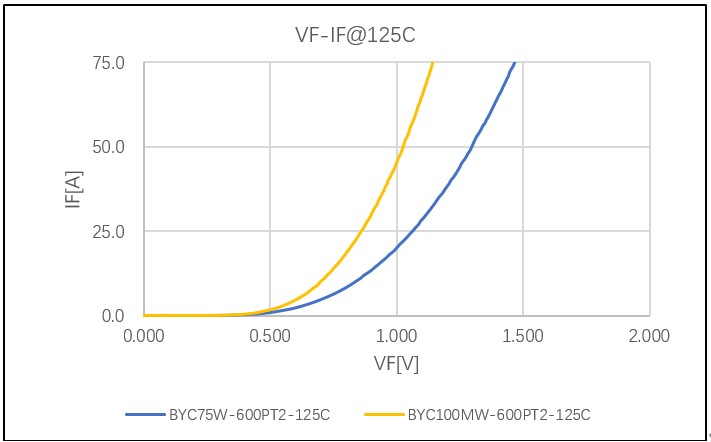

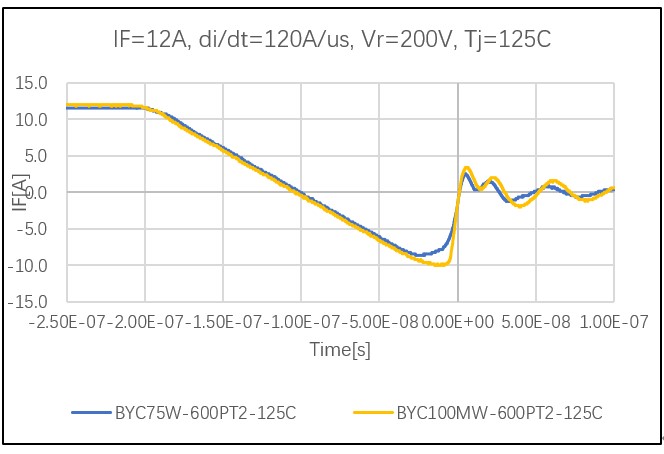

By comparing the specifications of the BYC100MW-600PT2 and BYC75W-600PT2, we find that the BYC100MW-600PT2 offers significant improvements in forward voltage (VF) while maintaining the same reverse recovery charge. As a result, it is more suitable for applications in 40kW high-power charging modules. Customers using the 40kW modules have observed an actual temperature rise reduction of 8°C to 10°C, which substantially enhances the thermal design of the system.

Figure 4: BYC100MW-600PT2 VF Curve

Figure 5: BYC100MW-600PT2 Qrr Curve

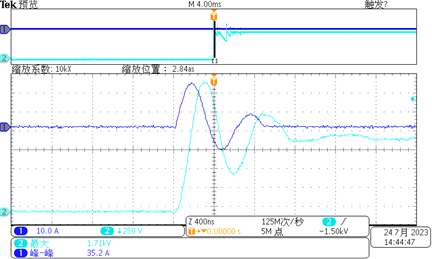

In the context of charging station applications, considering that there is quite a distance from the output of the charging module to the high-voltage power battery, potentially up to 30-40 meters, it is important to note that at the moment the charging module begins outputting, stray inductance in the charging cable and capacitors within the system will oscillate. This causes the diode to endure a spike in reverse voltage. If the voltage exceeds the diode’s avalanche voltage, it will cause avalanche breakdown; if the diode’s avalanche energy is insufficient, it will be damaged.

The WND60P20W is an enhancement of the existing WND60P16W product from WeEn Semiconductors, with the reverse withstand voltage increased to 2000Vdc while also improving its capability to withstand avalanche breakdown. The WND60P20W can meet the increasingly complex and harsh working environments of charging modules, providing greater safety margins for customer module designs.

Figure 6: Voltage Oscillation Across Oring Diode

About WeEn Semiconductors

WeEn specializes in the field of power semiconductors, inheriting over 50 years of core technology. With global sales points spreading across Greater China, Europe, Asia-Pacific, and the Americas, its products are applied in industries such as smart home appliances, electric vehicles, and communication industries, providing reliable and professional technical support for customers in their respective sub-industries. WeEn Semiconductors, mastering independent power semiconductor technology, has had its products verified and used by many well-known companies worldwide due to their excellent quality and performance.

For more information, please visit https://www.ween-semi.com